Hole Expansion Process . materials resistance to edge fracture in intricate shape forming is commonly quantified by hole expansion. cold hole expansion is a crucial technology for enhancing the fatigue life of hole structures. currently, the hole expansion test is the only test procedure that is defined by norms (jfs and iso). the hole expansion test is a test method applied in the metalworking industry and is used to determine the ductility of the edges on punched sheet metal. Shearing processes, such as blanking and punching, are commonly used in sheet metal stamping. a high hole expansion ratio (her) implies an improved edge quality in cutting and reduced mechanical work.

from hill-engineering.com

materials resistance to edge fracture in intricate shape forming is commonly quantified by hole expansion. Shearing processes, such as blanking and punching, are commonly used in sheet metal stamping. the hole expansion test is a test method applied in the metalworking industry and is used to determine the ductility of the edges on punched sheet metal. a high hole expansion ratio (her) implies an improved edge quality in cutting and reduced mechanical work. cold hole expansion is a crucial technology for enhancing the fatigue life of hole structures. currently, the hole expansion test is the only test procedure that is defined by norms (jfs and iso).

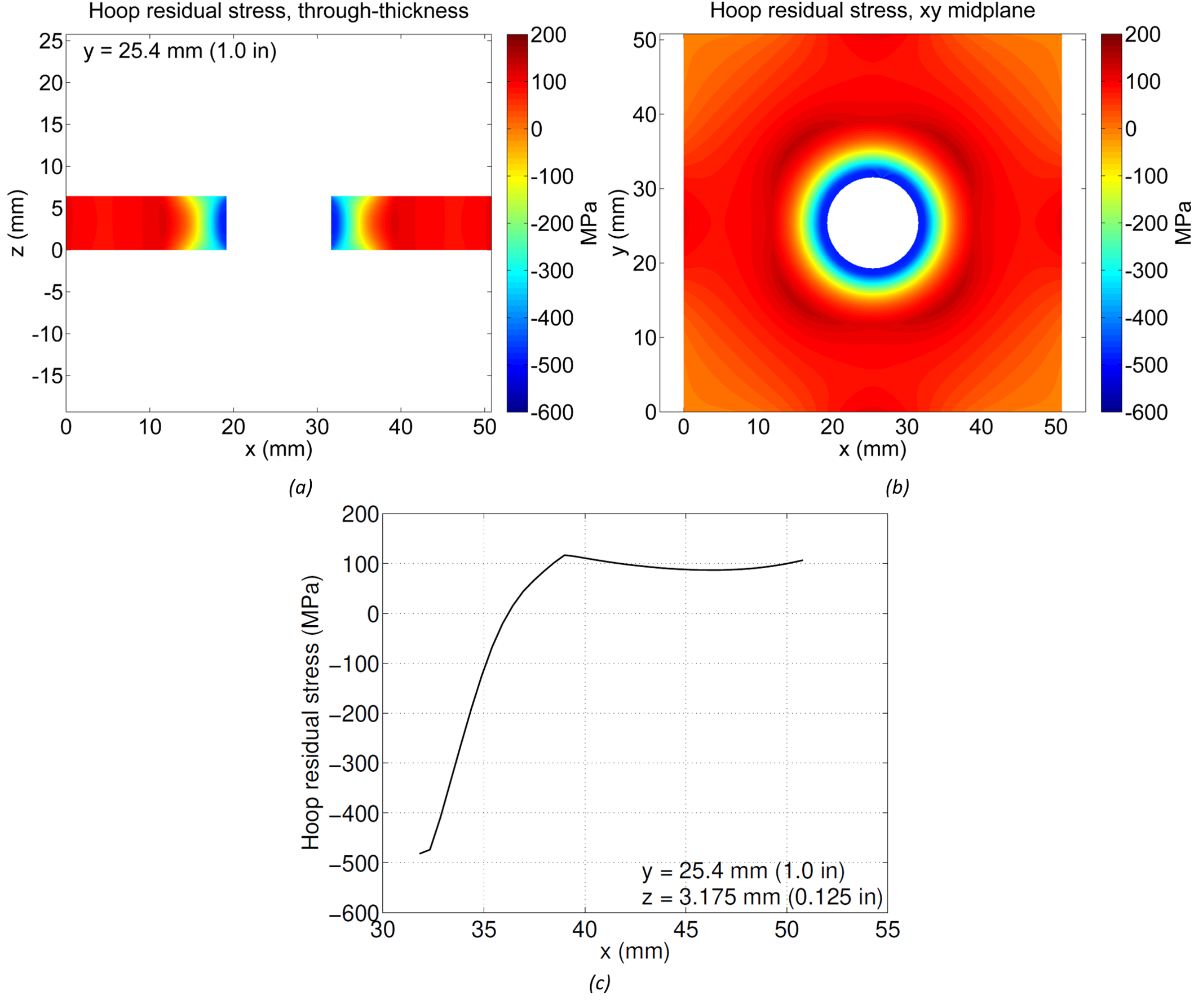

Case Study Cold hole expansion process modeling Hill Engineering

Hole Expansion Process currently, the hole expansion test is the only test procedure that is defined by norms (jfs and iso). Shearing processes, such as blanking and punching, are commonly used in sheet metal stamping. currently, the hole expansion test is the only test procedure that is defined by norms (jfs and iso). materials resistance to edge fracture in intricate shape forming is commonly quantified by hole expansion. cold hole expansion is a crucial technology for enhancing the fatigue life of hole structures. the hole expansion test is a test method applied in the metalworking industry and is used to determine the ductility of the edges on punched sheet metal. a high hole expansion ratio (her) implies an improved edge quality in cutting and reduced mechanical work.

From www.mdpi.com

Materials Free FullText Prediction of Hole Expansion Ratio for Hole Expansion Process the hole expansion test is a test method applied in the metalworking industry and is used to determine the ductility of the edges on punched sheet metal. Shearing processes, such as blanking and punching, are commonly used in sheet metal stamping. cold hole expansion is a crucial technology for enhancing the fatigue life of hole structures. a. Hole Expansion Process.

From www.researchgate.net

Schematic diagram of specimen and tool for hole expansion test (all Hole Expansion Process a high hole expansion ratio (her) implies an improved edge quality in cutting and reduced mechanical work. Shearing processes, such as blanking and punching, are commonly used in sheet metal stamping. currently, the hole expansion test is the only test procedure that is defined by norms (jfs and iso). cold hole expansion is a crucial technology for. Hole Expansion Process.

From www.researchgate.net

Hole expansion forming (a) geometry of the experimental apparatus and Hole Expansion Process materials resistance to edge fracture in intricate shape forming is commonly quantified by hole expansion. Shearing processes, such as blanking and punching, are commonly used in sheet metal stamping. the hole expansion test is a test method applied in the metalworking industry and is used to determine the ductility of the edges on punched sheet metal. cold. Hole Expansion Process.

From www.researchgate.net

Schematic structure and sequence of the hole expansion test with Hole Expansion Process Shearing processes, such as blanking and punching, are commonly used in sheet metal stamping. currently, the hole expansion test is the only test procedure that is defined by norms (jfs and iso). cold hole expansion is a crucial technology for enhancing the fatigue life of hole structures. the hole expansion test is a test method applied in. Hole Expansion Process.

From www.researchgate.net

Scheme and geometry of the hole expansion process. Download Hole Expansion Process cold hole expansion is a crucial technology for enhancing the fatigue life of hole structures. materials resistance to edge fracture in intricate shape forming is commonly quantified by hole expansion. currently, the hole expansion test is the only test procedure that is defined by norms (jfs and iso). the hole expansion test is a test method. Hole Expansion Process.

From www.researchgate.net

Hole expansion test setup (all dimensions are in mm) Download Hole Expansion Process currently, the hole expansion test is the only test procedure that is defined by norms (jfs and iso). materials resistance to edge fracture in intricate shape forming is commonly quantified by hole expansion. the hole expansion test is a test method applied in the metalworking industry and is used to determine the ductility of the edges on. Hole Expansion Process.

From www.researchgate.net

The model of column hole expansion. Download Scientific Diagram Hole Expansion Process currently, the hole expansion test is the only test procedure that is defined by norms (jfs and iso). the hole expansion test is a test method applied in the metalworking industry and is used to determine the ductility of the edges on punched sheet metal. Shearing processes, such as blanking and punching, are commonly used in sheet metal. Hole Expansion Process.

From www.researchgate.net

Hole expansion forming (a) geometry of the experimental apparatus and Hole Expansion Process materials resistance to edge fracture in intricate shape forming is commonly quantified by hole expansion. Shearing processes, such as blanking and punching, are commonly used in sheet metal stamping. the hole expansion test is a test method applied in the metalworking industry and is used to determine the ductility of the edges on punched sheet metal. cold. Hole Expansion Process.

From www.researchgate.net

Schematic diagram of (a) hole punching and (b) the hole expansion test Hole Expansion Process currently, the hole expansion test is the only test procedure that is defined by norms (jfs and iso). a high hole expansion ratio (her) implies an improved edge quality in cutting and reduced mechanical work. Shearing processes, such as blanking and punching, are commonly used in sheet metal stamping. the hole expansion test is a test method. Hole Expansion Process.

From www.researchgate.net

Implementation of friction stir hole expansion (FSHE) method Hole Expansion Process currently, the hole expansion test is the only test procedure that is defined by norms (jfs and iso). a high hole expansion ratio (her) implies an improved edge quality in cutting and reduced mechanical work. materials resistance to edge fracture in intricate shape forming is commonly quantified by hole expansion. the hole expansion test is a. Hole Expansion Process.

From www.researchgate.net

Test procedure of the "hole expansion with Nakajima punch" and "Kobe Hole Expansion Process materials resistance to edge fracture in intricate shape forming is commonly quantified by hole expansion. the hole expansion test is a test method applied in the metalworking industry and is used to determine the ductility of the edges on punched sheet metal. a high hole expansion ratio (her) implies an improved edge quality in cutting and reduced. Hole Expansion Process.

From www.researchgate.net

Experimental setup used for hole expansion deformation process Hole Expansion Process Shearing processes, such as blanking and punching, are commonly used in sheet metal stamping. the hole expansion test is a test method applied in the metalworking industry and is used to determine the ductility of the edges on punched sheet metal. materials resistance to edge fracture in intricate shape forming is commonly quantified by hole expansion. cold. Hole Expansion Process.

From www2.mdpi.com

Materials Free FullText Finite Element Analysis of Split Sleeve Hole Expansion Process the hole expansion test is a test method applied in the metalworking industry and is used to determine the ductility of the edges on punched sheet metal. materials resistance to edge fracture in intricate shape forming is commonly quantified by hole expansion. Shearing processes, such as blanking and punching, are commonly used in sheet metal stamping. currently,. Hole Expansion Process.

From www.researchgate.net

Mechanical model of cylindrical hole expansion. Download Scientific Hole Expansion Process currently, the hole expansion test is the only test procedure that is defined by norms (jfs and iso). the hole expansion test is a test method applied in the metalworking industry and is used to determine the ductility of the edges on punched sheet metal. cold hole expansion is a crucial technology for enhancing the fatigue life. Hole Expansion Process.

From www.researchgate.net

a Schematic view of the hole expansion experimental setup; b Initial Hole Expansion Process a high hole expansion ratio (her) implies an improved edge quality in cutting and reduced mechanical work. cold hole expansion is a crucial technology for enhancing the fatigue life of hole structures. materials resistance to edge fracture in intricate shape forming is commonly quantified by hole expansion. the hole expansion test is a test method applied. Hole Expansion Process.

From www.researchgate.net

Hole expansion ratio of the specimens corresponding to the initial hole Hole Expansion Process a high hole expansion ratio (her) implies an improved edge quality in cutting and reduced mechanical work. Shearing processes, such as blanking and punching, are commonly used in sheet metal stamping. currently, the hole expansion test is the only test procedure that is defined by norms (jfs and iso). cold hole expansion is a crucial technology for. Hole Expansion Process.

From www.researchgate.net

Schematical diagram showing the relationship between the holeexpansion Hole Expansion Process Shearing processes, such as blanking and punching, are commonly used in sheet metal stamping. a high hole expansion ratio (her) implies an improved edge quality in cutting and reduced mechanical work. the hole expansion test is a test method applied in the metalworking industry and is used to determine the ductility of the edges on punched sheet metal.. Hole Expansion Process.

From hill-engineering.com

Case Study Cold hole expansion process modeling Hill Engineering Hole Expansion Process materials resistance to edge fracture in intricate shape forming is commonly quantified by hole expansion. a high hole expansion ratio (her) implies an improved edge quality in cutting and reduced mechanical work. cold hole expansion is a crucial technology for enhancing the fatigue life of hole structures. Shearing processes, such as blanking and punching, are commonly used. Hole Expansion Process.